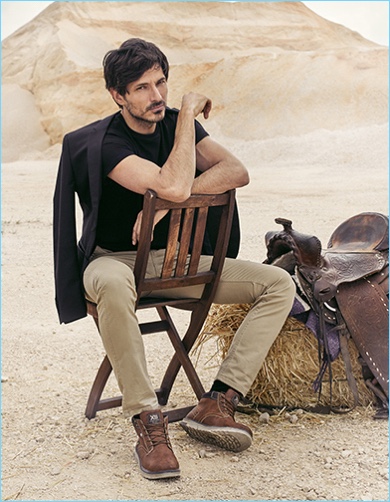

Xti Ankle boots 140056 brown - Height 7cm wedge - ESD Store fashion, footwear and accessories - best brands shoes and designer shoes

アイライン ライトカバー スバルWRX XTI 2018-2020 LED DRLデイタイムランニングライト フォグランプ リミテッドライト 1sest :s-01754:サカストア - 通販 - Yahoo!ショッピング

Madrid, Spain. 10th May 2018. Alessandra Ambrosio coleccion de Xti ALESSANDRA AMBROSIO; 10/05/2018 Model Alessandra Ambrosio during act of firm " XTI " in Madrid on Thursday 10 May 2018 CordonPress/EP888 Credit:

Compressive Tuning XTi Type One Roof Spoiler 2014-2018 ForesterDefault Title in 2023 | Subaru forester, Roof, Spoiler